Dry Scrubber Design and Humidity Control

What Is a Dry Scrubber?

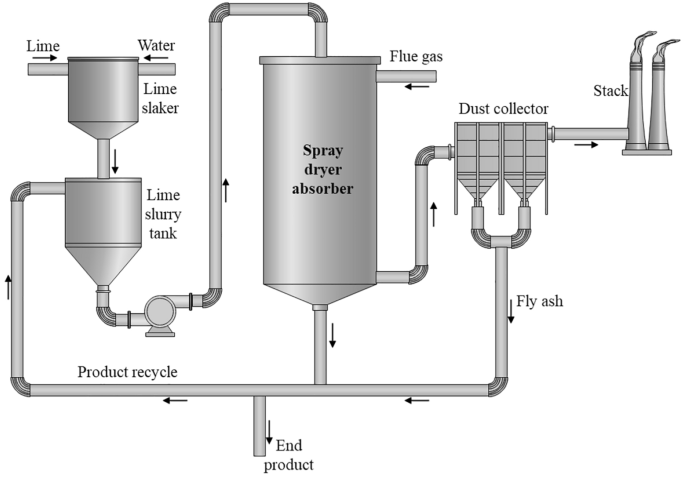

- In dry scrubbing, lime is injected directly into flue gas to remove SO2 and HCl. There are two major dry processes: “dry injection” systems inject dry hydrated lime into the flue gas duct and “spray dryers” inject an atomized lime slurry into a separate vessel. A spray dryer is typically shaped like a silo, with a cylindrical top and a cone bottom. Hot flue gas flows into the top. Lime slurry is sprayed through an atomizer (e.g., nozzles) into the cylinder near the top, where it absorbs SO2 and HCl. The water in the lime slurry is then evaporated by the hot gas. The scrubbed flue gas flows from the bottom of the cylindrical section through a horizontal duct. A portion of the dried, unreacted lime and its reaction products fall to the bottom of the cone and are removed. The flue gas then flows to a particulate control device (e.g., a baghouse) to remove the remainder of the lime and reaction products. Both dry injection and spray dryers yield a dry final product, collected in particulate control devices. At electric generating plants, dry scrubbing is used primarily for low-sulfur fuels. At municipal waste-to-energy plants, dry scrubbing is used for removal of SO2 and HCl. Dry scrubbing is used at other industrial facilities for HCl control. Dry scrubbing methods have improved significantly in recent years, resulting in excellent removal efficiencies.

What is a Wet Scrubber?

- In wet lime scrubbing, lime is added to water and the resulting slurry is sprayed into a flue gas scrubber. In a typical system, the gas to be cleaned enters the bottom of a cylinder-like tower and flows upward through a shower of lime slurry. The sulfur dioxide is absorbed into the spray and then precipitated as wet calcium sulfite. The sulfite can be converted to gypsum, a salable by-product. Wet scrubbing treats high-sulfur fuels and some low-sulfur fuels where high-efficiency sulfur dioxide removal is required. Wet scrubbing primarily uses magnesium-enhanced lime (containing 3-8% magnesium oxide) because it provides high alkalinity to increase SO2 removal capacity and reduce scaling potential.

Types of Scrubbers (Wet and Dry)

- Packed Bed Venturi Scrubber – Wet

- Spray Dryer Adsorber – Dry

- Wet Lime Scrubber – Wet

NID Scrubber – Dry

CFB (Circulating Fluid Bed) Scrubber – Dry

What Pollutants do Dry Scrubbers Remove?

Ammonia

Chlorine

Hydrochloric Acid

Chlorinated Silanes

Metallic Compounds

Sulfur Dioxide

Hydrogen Sulfide

Boron Trifluoride

Amines

How Effective are Dry Scrubbers?

Pollutant removal efficiency of dry scrubbers depends on various parameters within the process. To obtain high removal rates the distribution of sorbent across the reactor must be uniform and given an adequate residence time at a proper temperature. Flue gas must be kept 20F-50F above saturation temperature to minimize deposits building in the absorber and baghouse. Dropping below this range will likely require maintenance.

SO2 removal efficiencies are significantly lower than wet systems, between 50%-60% for calcium based sorbents while wet scrubbers are at near 95% efficient. Newer retrofit dry scrubbers installed on small coal-fired boilers have obtained removal efficiencies upwards of 90% though.

Dry Scrubber Advantages and Disadvantages

Advantages

- Less residual waste disposal costs

- Can be retrofitted into current equipment in most cases

- No waste water removal cost

- Uses less water

- Smaller space footprint

Disadvantages

- The control efficiency of acid gas is less than a wet scrubber although improving

- System is not able to remove all types of contaminants from gas

- Higher operating cost

Dry Scrubber Temp and Relative Humidity Control

Dry Scrubber SO2 removal efficiency is improved at lower scrubber outlet temperatures and higher relative

humidity. Learn how to monitor and optimize humidity, dew point temperature and

SO2 removal.

Scrubbers are currently designed to run at a thirty degree approach to dew point with a fixed moisture content used for the dew point calculation. Having an accurate and robust humidity sensor for control allows plants to always optimize the scrubber approach temperature and still prevent corrosion.

The dew point temperature of the flue gas for a coal fired boiler is dependent on the vapor pressure or volume fraction of water in the flue gas. So any ambient conditions or boiler auxiliary operations that

change the flue gas composition will also alter the saturation temperature of the flue gas. Unit

load, coal moisture variations, steam soot blowing, tube leaks and ambient air humidity changes

will affect the flue gas humidity content. Typical dry bulb temperature measurements cannot

detect changes in these humidity variables which result in less efficient and inherently higher risk

scrubber operation. Unit load, coal moisture variations and soot blowing cycles can possibly

change the moisture concentrations of the flue gas by 2 to 3% independently. Ambient air

humidity can change 1% by volume in a typical summer day (Table 1).

Table 1: Typical Ambient Data – Summer

| Time of Day | Dry Bulb Temperature (F) | Dew Point Temperature (F) | % Volume |

| 12:00 PM | 91 | 70 | 2.3 |

| 2:00 AM | 72 | 55 | 1.3 |

Table 2: Dew Point Temperature Change Based on 1% Volume Variance

| % Volume | Dry Bulb Temperature (F) | Dew Point Temperature (F) |

| 13% | 199 | 135.3 |

| 14% | 199 | 138.2 |

If the flue gas humidity content were to increase by 1% (Table 2) through any means, the operator would need to increase the scrubber outlet temperature by 3ºF to maintain the same safety margin.

Load condition plays an even larger role in flue gas humidity changes and with today’s plants running at lower loads at times, it is crucial to monitor the humidity. A change of 12 degrees in dew point can be seen from load changes in one day. A good rule of thumb is that every five degrees lower in approach to dew point temperature results in 5% in lime savings.

A humidity measurement is also very useful in identifying scrubber upsets such as nozzle erosion and plugging.

Feed Forward Scrubber Control

One approach is to install a humidity sensor prior to the dry scrubber, where the instrument can monitor the upstream moisture variables within the process and provide the added benefits of improved heat rate calculations, soot blower feedback and tube leak detection. An outlet dew point temperature can be calculated from the scrubber inlet humidity and the temperature drop across the scrubber. Scrubber upset conditions will not be identified with this type of control though. An alternative method is to install the instrument downstream of the scrubber and use the instrument’s output to directly control the water injection. This method has the advantage of being able to monitor scrubber upset conditions and detecting nozzle failures but will not be able to directly monitor tube leaks or other process variations like at the scrubber inlet. However, through careful monitoring of the system, operators should be able to detect tube leaks from a decrease in water injection rate needed to maintain humidity levels.

With the improved control on moisture injection and the ability to monitor the flue gas humidity

and flue gas dew point temperature in real-time, the plant should be able to increase SO2 removal

efficiency and improve limestone stoichiometry.

Humidity Sensor Installs