Wet Bulb Temperature Dryer Control Implementation

Detailed Drying Equation

According to the “Industrial Dryer Handbook” the wet bulb temperature is a key parameter in dryer control improvement. The following equation represents the correlation to product moisture and drying parameters:

X=K*LN((T1-Tw)/(T2-Tw)) where,

X= Product Moisture

K = is a dryer constant dependent upon product being dried and dryer design

T1 = Inlet Temperature

T2 = Outlet Temperature

Tw = Wet Bulb Temperature

In general, industrial dryers have not come equipped with wet bulb measurements due to reliability issues. Because of this, dryer control is typically conducted with the outlet dry bulb temperature controlling the inlet dry bulb temperature of the dryer.

The H2O sensor does work reliably in dryer exhaust gases so there is room for improved control in all dryers currently just using the dry bulb temperature control.

Wet Bulb Temperature Implementation

The best approach to implement the wet bulb temperature is to utilize H2O’s rental program where a sensor can be installed for a month and a business case established. The following parameters should be recorded for the trial:

Wet Bulb Temperature

Inlet Temperature

Outlet Temperature

Feed Rate

Air Flow

Manual Product Samples

The data is then trended under current dryer control to show sensor repeatability and establish trends in the data. The focus is to provide tighter control on the product moisture with it being as close to the allowable moisture specification. This will maximize profitability as well as optimize energy efficiency. Once the optimal product moisture (X) is determined, it is then used to establish the “K” value by inputting the value in the product equation and using the corresponding temperatures at the same time the optimal value was achieved in the data.

Once the K value and optimal product moisture (X) are determined, the control of the dryer can use both as inputs to the following equation for controlling the inlet temperature (T1):

T1=(e(X/K)*T2)-(e(X/K)*Tw)+Tw

This equation will tighten control and improve over outlet temperature alone.

Other control scenarios include predicting the outlet temperature for a given product moisture utilizing the wet bulb temperature and the inlet temperature as inputs. The following equation will solve for T2p:

T2p = (T1-Tw)/ e(X/K)+Tw

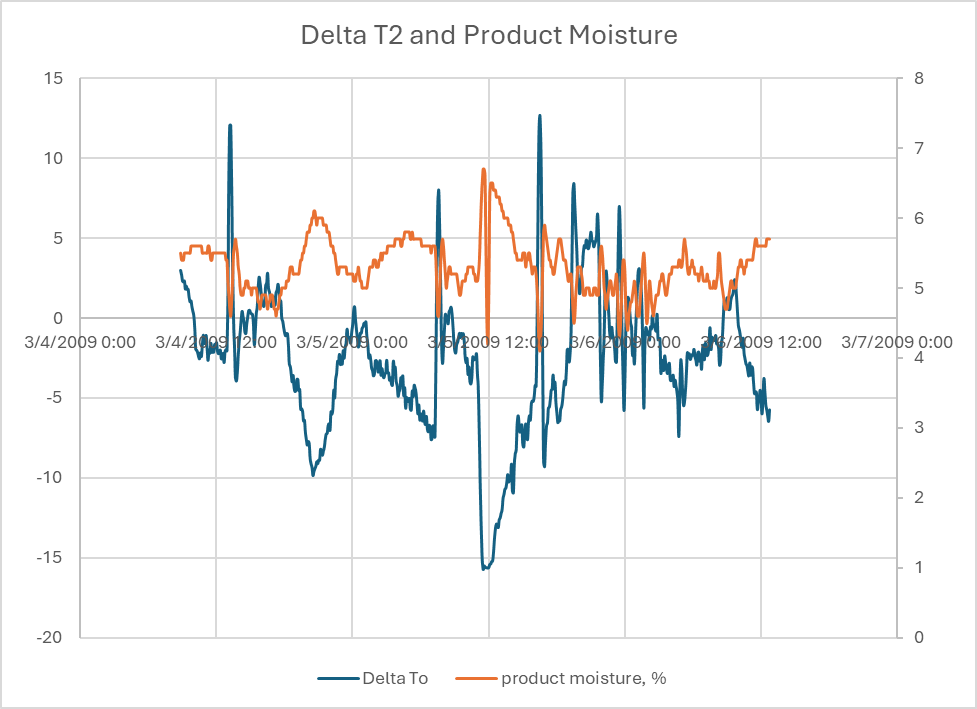

The difference between T2 and T2p has an inverse correlation to product moisture. The greater the difference of “T2-T2p”, the lower the product moisture will be to the target moisture.

Similarly, predicting the wet bulb temperature (Twp) for a desired product moisture utilizing the inlet temperature and outlet temperature as inputs also has the same effect but varies directly with product moisture. The following equation will solve for Twp:

Twp = (e(X/K)*T2 – T1)/ (e(X/K) – 1)

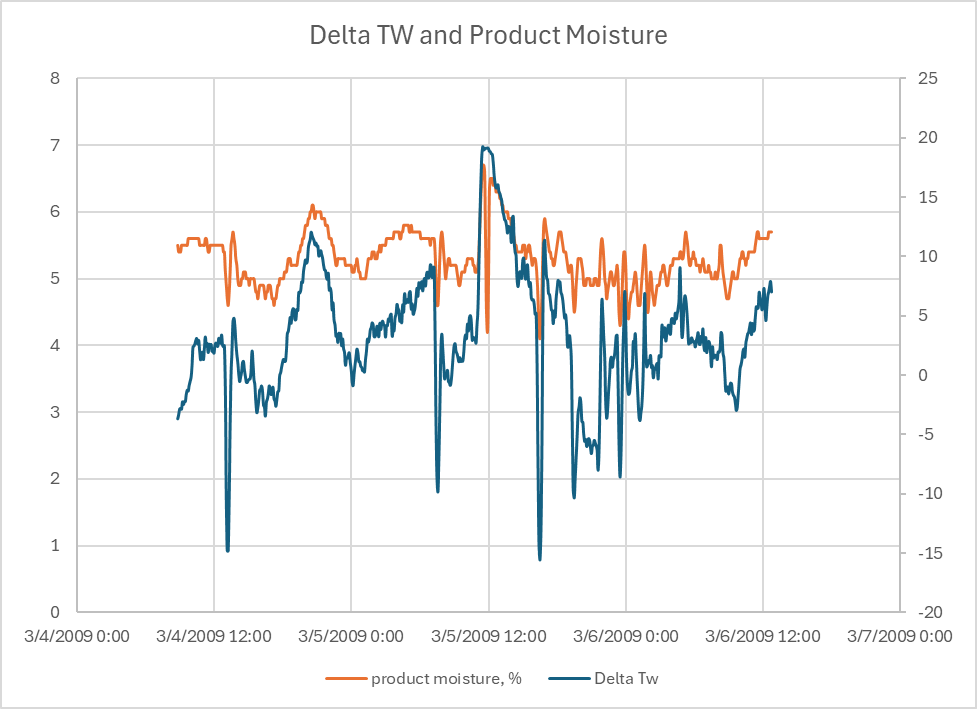

The difference between Tw and Twp has a direct correlation to product moisture. The greater the difference of “Tw-Twp”, the greater the product moisture will be to the target moisture.

For existing dryers, these two equations can be used as a check to assure the dryer is controlling close to the target moisture. The ideal differences will be zero. As the product moisture strays from the target, the differences will diverge. These equations can be easily developed for any dryer currently using just outlet temperature as the setpoint to control the dryer.

Below are two graphs showing these correlations with product moisture for a corn gluten flash dryer which used outlet temperature as the dryer control setpoint:

The concept is repeatable for all adiabatic dryers and can provide immediate dryer improvement.