Flash Dryer Product Moisture Control Utilizing Wet Bulb Temperature

In a recent test on a flash dryer, we tested out the product moisture prediction equation found in “The Handbook of Industrial Drying, Fourth Edition” for flash dryers:

X=K1*ln (Ti-Tw/To-Tw), where: Equation 1

X= product moisture

K1 = constant for the dryer and product dried

Ti =Inlet Temperature

To = Outlet Temperature

Tw = Wet bulb temperature

From Equation 1, we can derive equations 2 and 3:

K3= (To-Tw)/(Ti-Tw) or To=K3*Ti + (1-K3)*Tw Equation 2

K2=(Ti-Tw)/(To-Tw) or 1/K3 Equation 3

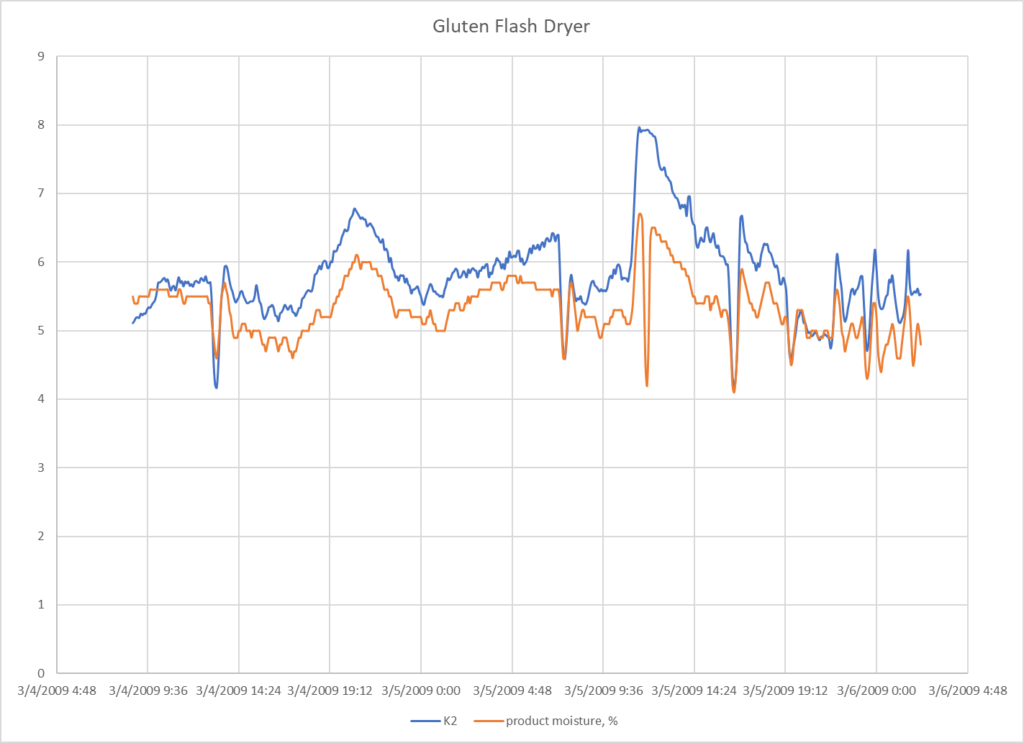

K2 tracks the product moisture value very closely. In the chart below, the K2 is charted with a real product analyzer on a gluten flash dryer. K2 involves measuring the wet bulb temperature in addition to inlet and outlet temperature. It provides tighter product moisture control.

There are two ways to implement this type of control.

Scenario 1 is to start the dryer as usual and once it gets to steady state, you control to a fixed K2 value by varying the inlet temperature. The outlet temperature will float.

Scenario 2 is to control the wet bulb temperature to a constant value if gas recycle is possible, you then use equation 2 above to control to a fixed outlet temperature by varying the inlet temperature.

The K values do have to be determined for each product being run on the dryer. But once done, the values are repeatable.